-40%

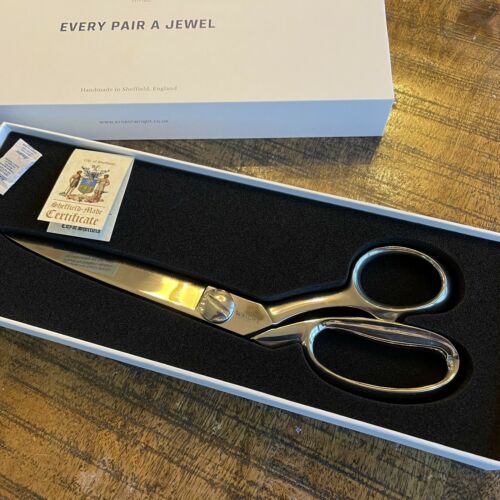

BRAND NEW - Ernest Wright Handmade 10” Tailor Shears

$ 132

- Description

- Size Guide

Description

These scissors are well renowned and backordered from the manufacturer up to 21 weeks. I accidentally ordered 2 and waited 7 months for them to arrive.Here’s the manufacturer’s website to learn more:

https://www.ernestwright.co.uk/product/tailor-shears-10-inch/

Watch a documentary on the process:

https://vimeo.com/98953952

BRAND NEW - Ernest Wright Handmade 10” Tailor Shears.

The 10″ Tailor shears (or 10″ Dressmaker shears) is a high quality tool for professional use. An outstanding product, used by tailors over the world. It’s perfect to cut through most fabric, and is a real eye-catcher with its mirror polish finished, 6″ blades. As all our products, these shears are hand-made with professional quality. So you can cut with ease, optimizing your workflow.

DETAILS

Type: Dressmaker shears / Tailor shears

Use: Tailors and dressmakers, cutting fabric

Total length: 10″ / 25.4 cm

Blade length: 6″ / 15.24 cm

Weight: 364 g

Material: Drop forged high quality carbon steel,

long-life precision edge retention

Finish: Hand polished

Packaging: High Quality presentation box

WE'LL PUT IN SOME EXTRA WORK

Once scissors have been forged and hardened, the surface of the handles is very rough, with burrs and scales. To make scissors pleasant to hold when in constant use, and as thumb and forefinger produce pressure for cutting, scissor handles require special processing.

Very often, the burrs are simply covered with a thick layer of paint. This process inadequately tries to avoid an old but very elaborate technique, namely that of flexible grinding which is the basic requirement for really smooth handles. In flexible grinding, scissor handles are precision-ground with the help of a large number of grinding discs and belts, differing in shape, hardness and grinding agent. Different tools are required for the various curves in the scissors’ handles. The insides of the handles are processed by stringing them on a grinding belt. Then the belt is placed on a moving roller and the handles are processed by being turned and guided.

This is a technique requiring great skill and experience and used to be an accepted part of processing scissors of professional quality. Right up until the Seventies, flexible grinding was a skilled occupation in Britain. Our craftsmen still use this technique to deliver the best possible scissors and shears.